What is color steel plate

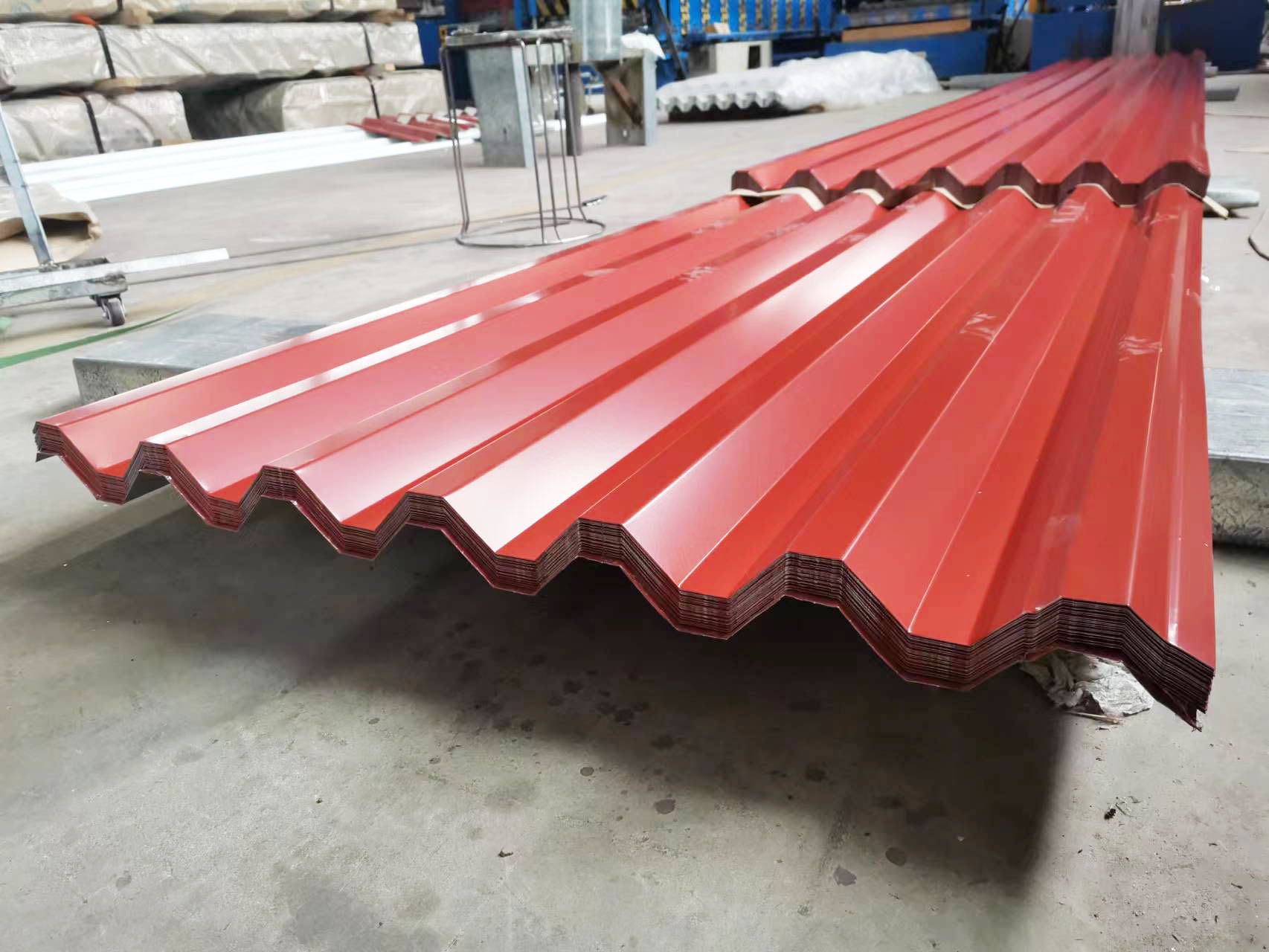

What is the color steel plate? Color steel plate, namely color coated steel plate, commonly known as color steel plate, is a steel product made of cold rolled steel plate, electro galvanized steel plate, hot galvanized steel plate or aluminum zinc plated steel plate after surface degreasing, phosphating, complexing treatment and transformation, coated with organic paint and baked.

The commonly used coatings for color steel plates are polyester (PE), followed by silicon modified resin (SMP), high weather resistant polyester (HDPE), polyvinylidene fluoride (PVDF), etc. The coating structure is divided into two layers of coating, one layer of baking and two layers of baking. The coating thickness is generally 20-25u on the surface, 8-10u on the back, and the external use of buildings should not be less than 20u on the surface and 10u on the back.

Color steel plate has the characteristics of light weight, high strength, bright color and good durability. Color steel plate is widely used in construction, household appliances, decoration, automobile and other fields.

The strength of color steel plate depends on the substrate material and thickness, and the durability depends on the coating (zinc plating amount 318g/m2) and surface coating. The coating is made of polyester, silicone resin, fluorine resin, etc. The coating thickness is more than 25um. The coating structure has two coats and one bake, two coats and two bake, etc. The maintenance free service life can be 20-30 years depending on the ambient atmosphere.

The commonly cited standards for color steel plate are ASTM A527 (galvanized), ASTM AT92 (aluminum zinc plated), JIS G3302 in Japan, EN/0142 in Europe, KS D3506 in South Korea, and Baosteel Q/BQB420.

Post time: Nov-14-2022